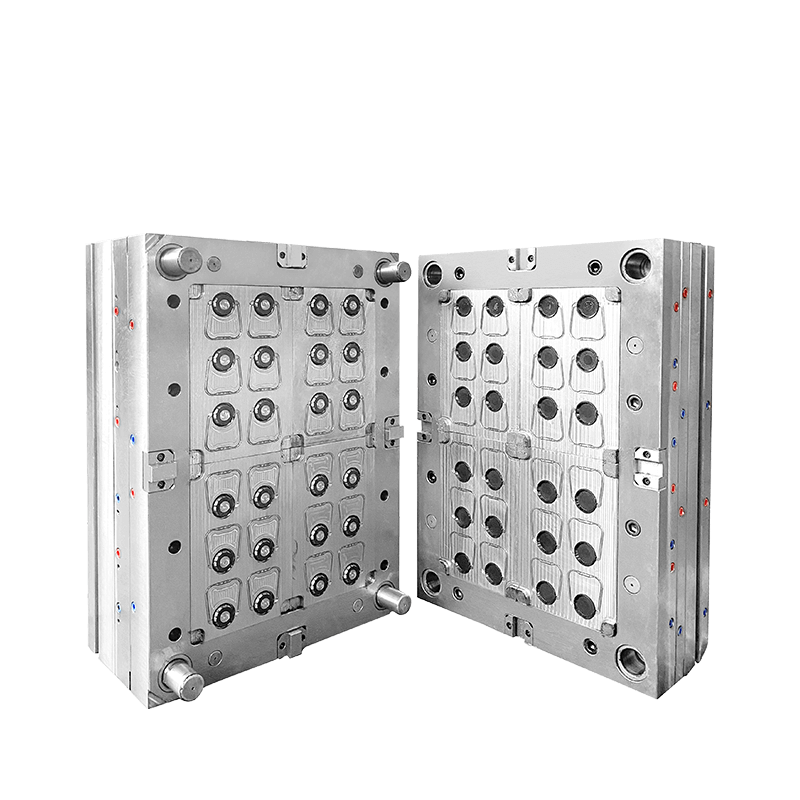

Mold Life Time: 3-5 million shots

Surface Request: High polish

Core& Cavity: S136

Mold Base: 2085

Runner System: Chinese brand/ YUDO

Mould gate type: Pin gate

Mould ejector type: Ejector pin

Package Details: Export Standard Seaworthy packing.(Wooden case)

Place of Origin: Taizhou, China

We pay great attention to mold quality:

1. Ensure the authenticity of the mold material: We will use S136 for the inserts, and 2085 for the mold base, the mould material are stainless material, you do not need to worry about the rust.

2. Advanced mould design: All of our molds has its own specialist mold structure, we will provide mold drawing for you to check.

3. Hot runner structure for easy replacement: The structure design of the nozzle is similar to that of the hot nozzle of the PET preform mold Replacing parts can be done on the machine.

FAQ:

1. What’s the specialist for this handle mould?

For this handle mould, each 6cavity with one insert plate, it’s easy to change. After long time running, if it is broken, you just need to change one insert, the maintenance cost is low.

2. Why the hot runner system is different for this mold?

The hot runner system is made by YUDO company, it’s customer’s requirement, all of you can choose different hot runner, we have relationship with YUDO, Husky, Master and so on.

3. Does the handle have enough load-bearing capacity?

Yes, the handle product is customized as customer’s needed, it’s totally strong enough.

4. Why the ejector pin locked?

After a long period of production, the thimble wears out, causing it to break, the quality of the ejector pin is very important, we will use SKD61 for the pin, it will not easy to break, and we will also provide spare parts for you.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur