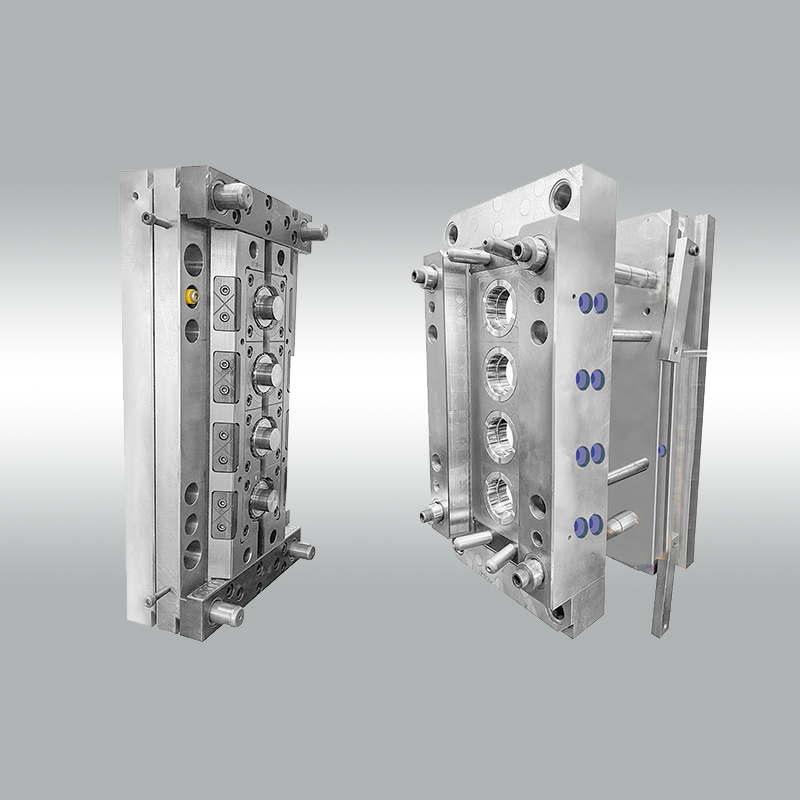

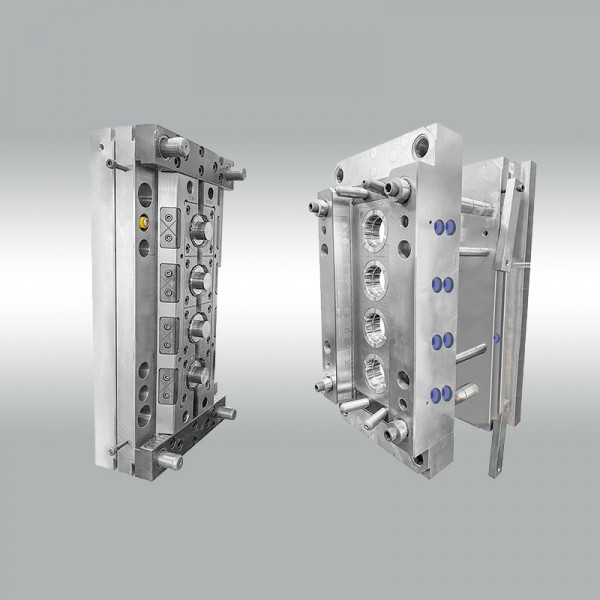

Mold Life Time: 3-5 million shots

Surface Request: High polish, High Gloss or Texture

Core& Cavity: H13/S136/2083/2344/2085/ASSAB STAVAX ESR

Mold Base: P20/ 4CR13/2085/2316

Runner System: Cold runner/Chinese brand/ YUDO/MASTER/HUSKY

Customization: Available

Mould Design: UG, CAD/CAM, PROE etc

mould processing: CNC, High speed carved, Digital controller lathe etc

mould gate type: Pin gate, Submarine gate, Valve gate etc

mould ejector type: Unscrew by motor, stripper plate, ejector sleeve, ejector pin

Package Details: Export Standard Seaworthy packing.

Place of Origin: Taizhou, China

We pay great attention to mold quality:

1.Ensure the authenticity of the mold material: We will provide the original certificate of country of origin of the material and the original heat proof of the material. The material with high purity, good toughness and good polishability is preferred. Germany's steel and Sweden's ASSAB materials are in the form of direct sales from the original factory, preventing material counterfeiting.

2.Advanced mould design: Cooperate with high-end mold companies all over the world, and have advanced mold design concepts and advanced mold structure design drawings.

3.Hot runner structure for easy replacement: The structure design of the nozzle is similar to that of the hot nozzle of the PET preform mold Replacing parts can be done on the machine.

FAQ:

After disassembling the mold, we checked the mould part is good, and we assemble the mold, but the product is still whitening, What shall we do for it?

(1): Insufficient plasticizing ability, (2): resin thermal decomposition, (3): Retained in the cylinder and partially overheated, (4): Injection speed is too fast, (5): injection pressure is too high, (6): Air is mixed in the screw (insufficient back pressure)

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur