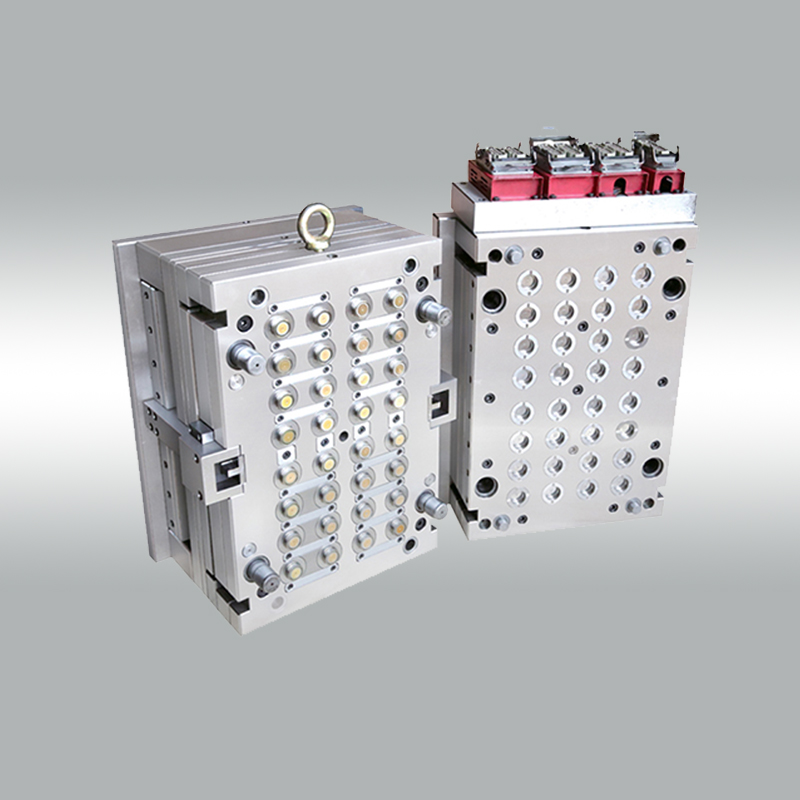

Famous Best Plastic Filter Cap Mould Factory - 12 Cavities Milk Cap Mould With Hot Runner – Aisen Detail:

Mold Life Time: 3-5 million shots

Surface Request: High polish, High Gloss or Texture

Core& Cavity: H13/S136/2083/2344/2085/ASSAB STAVAX ESR

Mold Base: P20/ 4CR13/2085/2316

Runner System: Cold runner/Chinese brand/ YUDO/MASTER/HUSKY

Customization: Available

Mould Design: UG, CAD/CAM, PROE etc

mould processing: CNC, High speed carved, Digital controller lathe etc

mould gate type: Pin gate, Submarine gate, Valve gate etc

mould ejector type: Unscrew by motor, stripper plate, ejector sleeve, ejector pin

Package Details: Export Standard Seaworthy packing.

Place of Origin: Taizhou, China

We pay great attention to mold quality:

1.Ensure the authenticity of the mold material: We will provide the original certificate of country of origin of the material and the original heat proof of the material. The material with high purity, good toughness and good polishability is preferred. Germany’s steel and Sweden’s ASSAB materials are in the form of direct sales from the original factory, preventing material counterfeiting.

2.Advanced mould design: Cooperate with high-end mold companies all over the world, and have advanced mold design concepts and advanced mold structure design drawings.

3.Hot runner structure for easy replacement: The structure design of the nozzle is similar to that of the hot nozzle of the PET preform mold Replacing parts can be done on the machine.

FAQ:

We used high MFI material for this product, but the parting line is clearly, what’s the mould problem?

(1): The glue flow from the gate to the weld line is too long and the mold temperature is too low, (2): The location and quantity of the gate are not appropriate, (3): The gate and the runner are too small, (3): The exhaust is not good, (4): Excessive use of release agent

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for Famous Best Plastic Filter Cap Mould Factory - 12 Cavities Milk Cap Mould With Hot Runner – Aisen , The product will supply to all over the world, such as: Russia, Hungary, India, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.